Our Process

01.Concept Planning

Your design experience begins here. We will begin the customisation process by discussing your vision with our jewellery design team.

Show us images or real samples of what you want done to give us examples and suggestions. We need every detail regarding your bespoke jewellery vision.

Our crew has been trained in numerous CAD-CAM jewellery design programmes and can develop any design concept you can conceive of. We urge all of our customers to participate in the custom design process.

All pieces are available in all gold hues (Yellow, White, Red/Rose/Pink, and Green), as well as all gold Karats (10k, 14k, 18k, 19k, and 22k), Sterling Silver, Copper, Brass, Bronze, Platinum, and Titanium.

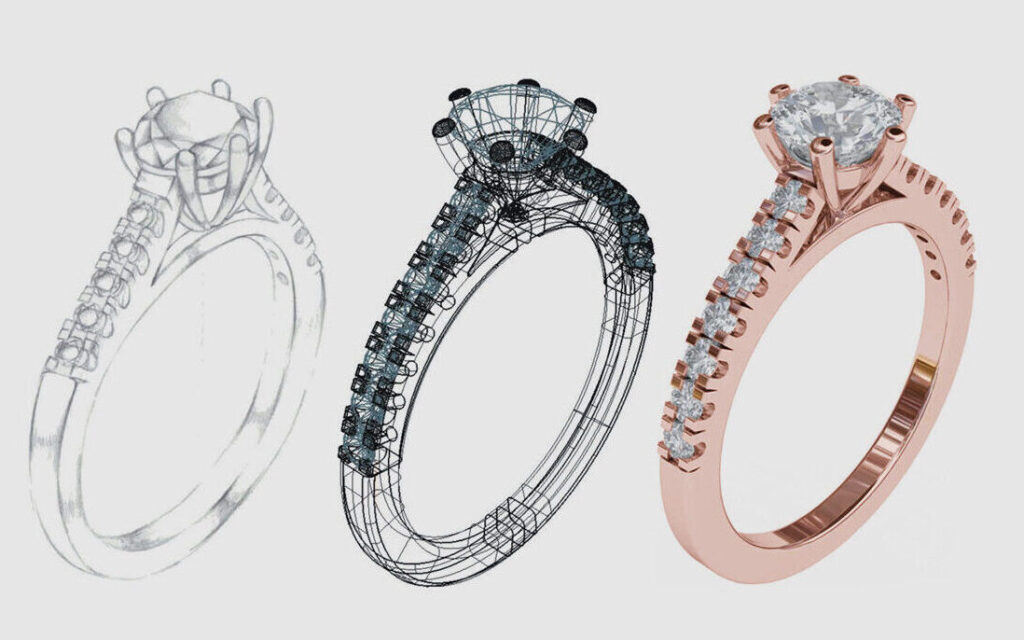

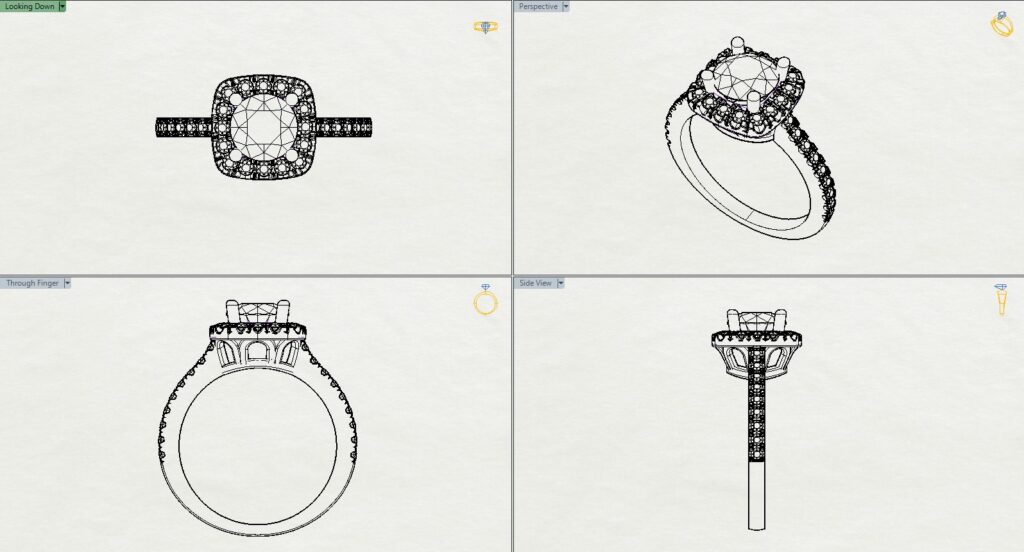

We will provide you with a 3D rendering of your bespoke artwork. This is a digital representation of your design concept. We will be able to edit and tweak the design as much as you want at this point before we begin to bring it to life.

02. Customization

Dave Crawford, our in-house metal casting expert and jewellery producer, will take your idea and turn it into a reality!

Dave is in charge of developing the idea into a wax prototype.

Our 3D printer makes tiny wax patterns for direct metal casting and precision jewellery patterns. This instrument is essential in the process of creating customised jewellery.

We will use our CNC machines to cut metal dies for the most intricate designs. The prototypes are then created by injecting wax into the dies at a very high temperature. This process yields the most detailed components imaginable.

03. Manufacturing

The exciting part following that is the lost wax investment casting process. A series of techniques are used to create an investment metal casting. Your preferred substance will be injected into the cast. You can also personalise your material of choice.

Finally, our skilled jewellers will polish, place stones, and polish and check the piece.

Designer Consulting

Our skilled designers and production team will help you make your new jewellery design ideas come to life.

3D cAD works

When CAD is used throughout the jewellery-making process, designs that are thought of that can be accurately sketched for early visualisation, and test models can be 3D printed before they are cast.

3D Printing

Anyone can make one-of-a-kind jewellery with 3D printing. 3D printing has changed the jewellery market and led to modern jewellery companies that create personalised jewellery a sought-after craftsmanship.

Finishing

Our Design Team can also follow up on your finishing needs.

- Cleaning

- Polishing

- Assembly

- Setting

- Stone Supply and setting

We use state-of-the-art printing machines to give you high-quality products at competitive prices that are made at the best resolution in the industry. We use the most advanced technology in the industry to give you prototypes with the best resolution available at competitive prices. These are the best printers used in the jewellery business.

Satisfaction Guarantee: If you’re not happy with the surface quality of the wax model or prototype, we’ll reprint it for free until it meets or exceeds your standards.

Our Collections

Personal Illusions creates bespoke pieces of earrings, pendants, bracelets, broaches, lapel pins, tie tacks, and cufflinks.

We also make personalised Signet Rings, Coat of Arms Rings, Clan Rings, Masonic Rings, Military Rings, Police Rings, Championship Rings, Team Rings, Corporate Rings, Club Rings, and, of course, Engagement Rings and Wedding Bands that are all part of our collection.

Don’t see what you’re searching for? Not a problem!

Our designers can develop any design you can think of!